·ÇÇòĂæÄ„Ïśź

I(yšš)ÔO(shšš)Ó(jšŹ)

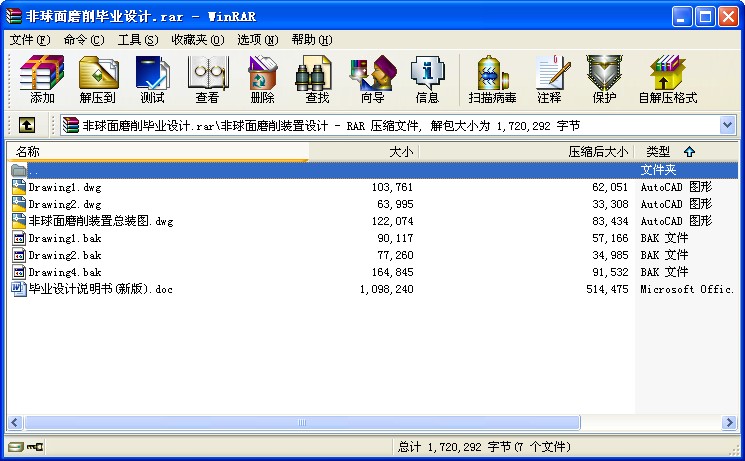

- ÎÄŒțœéœBŁș

- ÔÎÄŒțé rar žńÊœŁšÔŽÎÄŒțżÉŸĘŁ©�����ŁŹÏÂĘdĐèÒȘ

20 ·e·Ö

-

- ·ÇÇòĂæÄ„Ïśź

I(yšš)ÔO(shšš)Ó(jšŹ)

ŐȘ ÒȘ

·ÇÇòĂæčâW(xušŠ)ÁăŒțżÉÒÔ«@”ĂÇòĂæčâW(xušŠ)ÁăŒțożÉ±ÈM”ÄÁŒșÔijÉÏńÙ|(zhšŹ)Áż�����ŁŹÔÚčâW(xušŠ)Ï”œy(tšŻng)ÖĐÄÜòșÜșÔijCŐę¶à·NÏńČî�����ŁŹžÄÉÆłÉÏńÙ|(zhšŹ)ÁżŁŹÌážßÏ”œy(tšŻng)èbeÄÜÁŠ�����ŁŹËüÄÜÒÔÒ»(gšš)»òŚ(gšš)·ÇÇòĂæÁăŒțŽúÌæ¶à(gšš)ÇòĂæÁăŒț��ŁŹÄ¶űș(jišŁn)»ŻxÆśœY(jišŠ)(gš°u)���ŁŹœ””ͳɱŸČąÓĐЧ”ÄpĘpxÆśÖŰÁż���Ą��ŁżÉV·șȘ(yš©ng)ÓĂÓÚžś·NŹF(xiš€n)ŽúčâëŚÓźa(chšŁn)Æ·ŁŹŚșőÔÚËùÓĐ”Ä耳ÌȘ(yš©ng)ÓĂîI(lš«ng)ÓòÖĐ����ŁŹoŐÊÇŹF(xiš€n)Žúű·ÀżÆŒŒŒŒĐg(shšŽ)îI(lš«ng)Óò�����ŁŹßÊÇÆŐÍš”Äč€I(yšš)îI(lš«ng)Óò¶ŒÓĐÖűV·ș”ÄȘ(yš©ng)ÓĂÇ°Ÿ°�ŁŹé_ŐččâW(xušŠ)ČŁÁ§·ÇÇòĂæÁăŒț”Ğߟ«ĂÜčâW(xušŠ)ŒŒĐg(shšŽ)ŃĐŸżŸßÓĐÖŰÒȘ”ÄÀíŐÒâÁxșÍŹF(xiš€n)(shšȘ)Öž§(dšŁo)ÒâÁxĄŁ

±ŸŽÎÔO(shšš)Ó(jšŹ)ŃĐŸż?jš©)?nšši)ÈĘé·ÇÇòÇúĂæ”ÄłŹŸ«ĂÜŒÓč€Ï”œy(tšŻng)”ÄŃĐŸżŁŹ·ÇÇòÇúĂæ”ÄłŹŸ«ĂÜŒÓč€č€Ë”ÄŃĐŸż����ĄŁÖŰüc(dišŁn)È(nšši)ÈĘÊÇ·ÇÇòÇúĂæŒÓ耳ŹŸ«ĂÜÄ„ÏśŃbÖĂ”ÄÔO(shšš)Ó(jšŹ)���ŁŹÖśÒȘéÉ°ĘÖśĘSŃbÖĂ”ÄßxÈĄ����ŁŹÖĐĐÄžßλŐ{(diš€o)C(jš©)(gš°u)”ÄÔO(shšš)Ó(jšŹ)�ŁŹžś(gšš)ß\(yšŽn)Ó(dš°ng)”ÄśÓ(dš°ng)ÔO(shšš)Ó(jšŹ)ÒÔŒ°É°Ęß\(yšŽn)Ó(dš°ng)ÜÛE”Ä·ÖÎöĄŁÔÚŃĐŸżß^łÌÖĐÔŒ(xšŹ)”Ä·ÖÎöÁËÓ°íÁăŒțŒÓč€Ÿ«¶È”Äžś·NÖśÒȘÒòËŰČąÌáłöÏàȘ(yš©ng)”ÄżŰÖÆŽëÊ©ŁŹÓÈÆäÊÇŠ(dušŹ)·ÇÇòÇúĂæ”ÄÄ„ÏśŒÓč€ÔO(shšš)äßM(jšŹn)ĐĐÔŒ(xšŹ)ÔO(shšš)Ó(jšŹ)�ŁŹČąș(jišŁn)ÒȘ·ÖÎöÁË·ÇÇòÇúĂæŒÓč€C(jš©)ŽČ”Ä”(shšŽ)żŰŒ°ËĆ·țżŰÖÆÏ”œy(tšŻng)”È�ĄŁ

êP(gušĄn)æIÔ~Łș·ÇÇòÇúĂæ��Ł»łŹŸ«ĂÜŒÓč€���Ł»ÎąŐ{(diš€o)C(jš©)(gš°u)��Ł»œđÊŻÉ°Ę

Abstract

The aspheric optical parts can get good image quality, good optical system correction of various aberrations, to improve the image quality, and improve the system ability to identify it to one or several non-spherical spherical optical parts unparalleledparts instead of a number of spherical parts, thus simplifying the instrument structure, reduce costs and reduce instrument weight. ItĄŻs widely used in many realms, such as national defense, machine chemical and aviation. ItĄŻs very useful to develop the grinding theory and important practical significance to study the high precision grinding methods about the optical glass aspheric surface parts.

This article discussed in the ultra-precision grinder, the CNC operation program,and the aspheric surface optics partsĄŻ grinding craft. The center height micro-adjusting mechanism and the drive system. In the process of the research, we analysis it detailed that the main factor influence the process precision of the parts, and make something to solve it, especially for the precision grinding equipments, and analysis it simplify for the precision machine tool for aspheric surface optics parts and the servo-control system and the other technology.

Key words: the aspheric surface; ultra-precision machining; the micro-adjusting mechanism; diamond wheel

Äż ä

ŐȘÒȘ I

Äżä III

”Ú1ŐÂ ŸwŐ 1

1.1·ÇÇòĂæŒÓ耔Ä(yšu)üc(dišŁn)șÍÒâÁx 1

1.2·ÇÇòÇúĂæŃĐŸżžĆÊö 1

1.2.1 ·ÇÇòĂæ”ĶšÁx 1

1.2.2 ·ÇÇòĂæȘ(yš©ng)ÓĂîI(lš«ng)Óò 2

1.2.3 ·ÇÇòÇúĂæŒÓč€ŒŒĐg(shšŽ)œüÄêí°l(fšĄ)ŐčžĆr 2

1.2.4 ·ÇÇòÇúĂæŒÓ耔İl(fšĄ)ŐčÚ

Ę(shšŹ)șÍŃĐŸż·œÏò 4

1.3 ·ÇÇòĂæčâW(xušŠ)ÁăŒțČÄÁÏŒ°ÆäŒÓ耷œ·š 4

1.3.1 Ó(jšŹ)ËăC(jš©)”(shšŽ)żŰÎüc(dišŁn)œđÊŻŒŒĐg(shšŽ)ŁšSPDTŁ© 5

1.3.2 łŹŸ«ĂÜÄ„ÏśŒŒĐg(shšŽ) 5

1.3.3 Ó(jšŹ)ËăC(jš©)żŰÖÆčâW(xušŠ)±íĂæłÉĐÍŁšCCOSŁ©ŒŒĐg(shšŽ) 5

1.3.4 čâW(xušŠ)ČŁÁ§ÄŁșłÉĐÍŒŒĐg(shšŽ) 6

1.3.5 čâW(xušŠ)ËÜÁÏłÉĐÍŒŒĐg(shšŽ) 6

1.3.6 ÆäËû·ÇÇòĂæŒÓč€ŒŒĐg(shšŽ) 6

1.4·ÇÇòĂ柫ĂÜÄ„ÏśŒÓč€ÀíŐ 6

1.4.1 ÎąÁżŒÓč€ÀíŐ 7

1.4.2 ŽàĐÔČÄÁÏ”ÄŃÓĐÔÓòÄ„Ïś 8

”Ú2Ő łŹŸ«ĂÜ·ÇÇòĂæŒÓ耷œ°žßxńŒ°Ő`Čî·ÖÎö 10

2.1 łŹŸ«ĂÜ·ÇÇòÇúĂæÄ„ŽČ”ÄżówČŒŸÖ 10

2.1.1 żŐâÖśĘSÏ”œy(tšŻng) 10

2.1.2 ËĆ·țßM(jšŹn)œoÏ”œy(tšŻng) 11

2.1.3 ιλÒÆy(cšš)ÁżÏ”œy(tšŻng) 11

2.1.4 ÖĐĐÄžßÎąŐ{(diš€o)Ï”œy(tšŻng) 11

2.1.5 ”(shšŽ)żŰÏ”œy(tšŻng) 11

2.2 ·ÇÇòÇúĂæÄ„Ïś·œ°ž”ÄŽ_¶š 12

2.2.1ŒÓč€ÁăŒț”ÄŒŒĐg(shšŽ)

ą”(shšŽ) 13

2.2.2 ·ÇÇòÇúĂæÄ„Ïś·œ°žŽ_¶š 13

2.3 ŒÓč€Ő`Čî·ÖÎö 14

2.3.1 ÖĐĐÄžßÎąŐ{(diš€o)C(jš©)(gš°u)Š(dušŹ)ÁăŒțŒÓč€Ÿ«¶È”ÄÓ°í 15

2.3.2 ÔÚXĘSÉÏÉ°Ę°ČŃbŐ`ČîŠ(dušŹ)ÁăŒțŒÓč€Ÿ«¶È”ÄÓ°í 17

2.3.3 É°Ę°ëœŐ`ČîŠ(dušŹ)ÁăŒțŒÓč€Ÿ«¶È”ÄÓ°í 18

2.3.4 Œ° ŸCșÏŚśÓĂr(shšȘ)Š(dušŹ)ÁăŒțĂæĐΟ«¶È”ÄÓ°í 19

”Ú3Ő ·ÇÇòĂæÄ„ÏśŃbÖĂÔO(shšš)Ó(jšŹ) 21

3.1 łŹŸ«ĂÜŒÓ耔ÄêP(gušĄn)æIŒŒĐg(shšŽ) 21

3.1.1 łŹŸ«ĂÜÖśĘS 21

3.1.2 łŹŸ«Ăܧ(dšŁo)Ü 21

3.1.3 śÓ(dš°ng)Ï”œy(tšŻng) 22

3.1.4 łŹŸ«ĂÜ”¶Ÿß 22

3.1.5 łŹŸ«ĂÜŒÓč€ÆäËûŒŒĐg(shšŽ) 23

3.2 śÓ(dš°ng)Ï”œy(tšŻng)ÔO(shšš)Ó(jšŹ) 23

3.2.1 Ä„Ïś

ą”(shšŽ)”ÄÓ(jšŹ)Ëă 23

3.2.2 §(dšŁo)Ü”ÄŐûówÔO(shšš)Ó(jšŹ) 24

3.2.3 śÓ(dš°ng)

ą”(shšŽ)”ÄÓ(jšŹ)Ëă 25

3.3 Ä„ÏśÏ”œy(tšŻng)ÔO(shšš)Ó(jšŹ) 25

3.3.1 Ï”œy(tšŻng)œY(jišŠ)(gš°u)ÔO(shšš)Ó(jšŹ) 26

3.3.1 ÖĐĐÄžßÎąŐ{(diš€o)C(jš©)(gš°u)ÔO(shšš)Ó(jšŹ) 27

3.3.2 É°ĘÖśĘS”Äßxń 28

œY(jišŠ) Ő 31

ÖÂ Öx 32

ążŒÎÄ«I(xiš€n) 33

CONTENTS

Abstract I

CONTENTS III

Capter 1 Introduction 1

1.1 The meaning of the processing of aspheric surface 1

1.2 The introuduction of the aspheric surfaceĄŻs research 1

1.2.1 Definition of aspheric surface 1

1.2.2 Application of aspheric surface 2

1.2.3 The development of aspheric surface in recent years 2

1.2.4 Aspheric pricesssing trends and research directions 4

1.3 The partsĄŻ material and the processing method 4

1.3.1 Computer-controlled single-point diamond technologyŁšSPDTŁ© 5

1.3.2 Ultra-precision grinding technology 5

1.3.3 Computer Controlled Optical SurfacingŁšCCOSŁ© 5

1.3.4 Optical glass compression molding technology 6

1.3.5Optical plastic molding technology 6

1.3.6 Other processing technology 6

1.4Aspheric surface precision grinding theory 6

1.4.1 Trace processing theory 8

1.4.2 Ductile-regime grinding of brittle materials 8

Capter 2 Ultra-precision aspheric processing alternatives and error analysis 10

2.1 Ultra precision aspherical surface grinding machine layout 10

2.1.1 Air spindle system 10

2.1.2 Servo feed system 11

2.1.3 Micro-displacement measurement system 11

2.1.4 Center high tuning system 11

2.1.5 Numerical control system 11

2.2 Aspherical surface grinding scheme 12

2.2.1 Processing part of the technical parameters 13

2.2.2 Aspherical surface grinding scheme 13

2.3 Processing error analysis 14

2.3.1 Center high fine-tuning mechanism on the impact of cutting accuracy 15

2.3.2 In the X axis on the wheel on the impact of cutting accuracy 17

2.3.3 Wheel radius error on the part of machining precision 18

2.3.4 Both and on the part 19

Capter3 Aspheric tooling design 21

3.1 Ultra-precision machining technology 21

3.1.1 Ultra-precision spindle 21

3.1.2 Ultra-precision guide 21

3.1.3 Drive system 22

3.1.4 Ultra-precision cutter 22

3.1.5 Other technology 23

3.2 Transmission System Designing 23

3.2.1 Grinding parameters 23

3.2.2 The overall design of the Rails 24

3.2.3 Calculation of transmission parameters 25

3.3 Grinding systems design 25

3.3.1 System architecture design 26

3.3.1 Center high micro-adjusting mechanism design 27

3.3.2 Wheel spindle design 28

Conclusion 31

Thanks 32

References 33 ...

áéTêP(gušĄn)æIÔ~Łș

áéTêP(gušĄn)æIÔ~Łș

Ô„č«ŸW(wšŁng)°Čä 41072402000322Ì(hš€o)

Ô„č«ŸW(wšŁng)°Čä 41072402000322Ì(hš€o)